by Kara Brogan | Jul 9, 2025

As part of NES’s ongoing routine inspections at one of our major sites in Western NSW, a Condition Monitoring Technician recently identified a developing issue with a Boot End Pulley bearing. Through vibration analysis, data trends revealed the early onset of...

by Kara Brogan | Mar 21, 2025

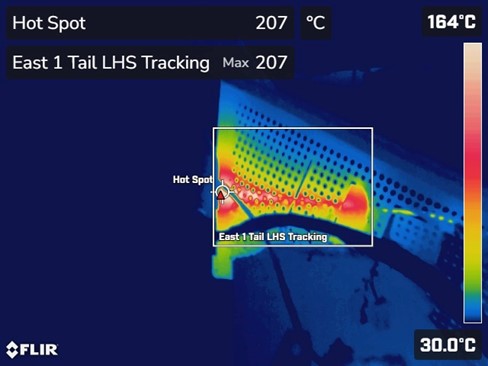

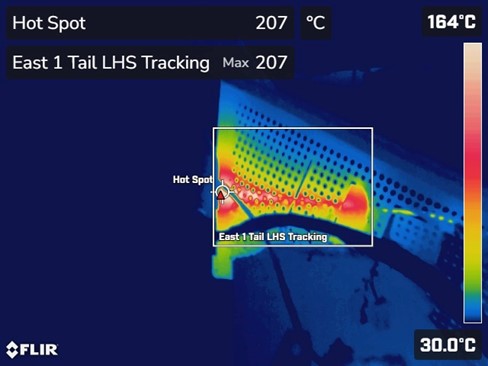

A routine survey conducted at an Underground site in the Newcastle Region of NSW resulted in NES Technicians identifying a potential fire hazard, which could have resulted in catastrophic outcomes for the site. During the survey of the underground coal mining...

by Kara Brogan | Mar 21, 2025

During a recent inspection conducted at a Hunter Valley based Coal Handling and Preparation Plant, our technician identified a drive pulley that was registering an elevated reading, indicating higher than normal vibration levels from the component. The reject...

by Brad Noble | Dec 6, 2021

Significant downtime on a critical mine ventilation fan was averted when increasing imbalance was tracked over 4 weeks and timely action was taken to repair the problem in a planned and controlled manner. Situation: During routine condition monitoring surveys on one...

by Brad Noble | Dec 3, 2021

Costly downtime from catastrophic failure was avoided when a conveyor drive pulley bearing mounting sleeve came loose and was found by NES on a routine condition monitoring survey. Situation: During a routine condition monitoring survey of the conveyor drive...